Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

Large frames, bridge sections, or heavy machinery often resist simple lifts because they twist or tilt when picked from two or three points. A 4 way chain rigging system adds redundancy and stability so crews balance loads evenly, reduce rotation, and protect structure integrity. This guide outlines practical geometry, sizing from Working Load Limit (WLL) tables, and inspection routines so operators handle four-leg slings with confidence. By following measurable steps and clear fit checks, rigging teams avoid re-rigs and keep every lift traceable.

Four legs distribute force across multiple points, reducing stress per connector and minimizing swing. A 4 way rig offers:

Stability: ideal for rectangular frames or skids with four engineered lift lugs.

Balance: allows load sharing across paired legs.

Flexibility: shorteners let you trim length to cancel roll or pitch.

Still, most WLL tables treat 3-leg and 4-leg assemblies as equal, since not all four legs always share load perfectly. Crews therefore size conservatively, assuming three legs carry the weight.

Angles to vertical (β\beta) set leg tension. Keep all legs between 15° and 60°. When possible, hold angles near 45° for predictable load sharing.

Angle Factors (check manufacturer’s table):

Sling Setup | Angle β (to vertical) | Planning Factor (×) | Notes |

2-leg vertical | 0°–45° | 1.4 | Default for stability |

3-leg / 4-leg | 0°–45° | 2.1 | Many tables rate both equally |

3-leg / 4-leg wide | 45°–60° | 1.5–1.6 | Tension rises as angle widens |

Choker hitch | — | 0.8 | Reduce 20% capacity |

Master link assembly: use one sized for four connectors, with sublinks to avoid crowding. Seat fully in the crane hook bowl, and check latch clearance.

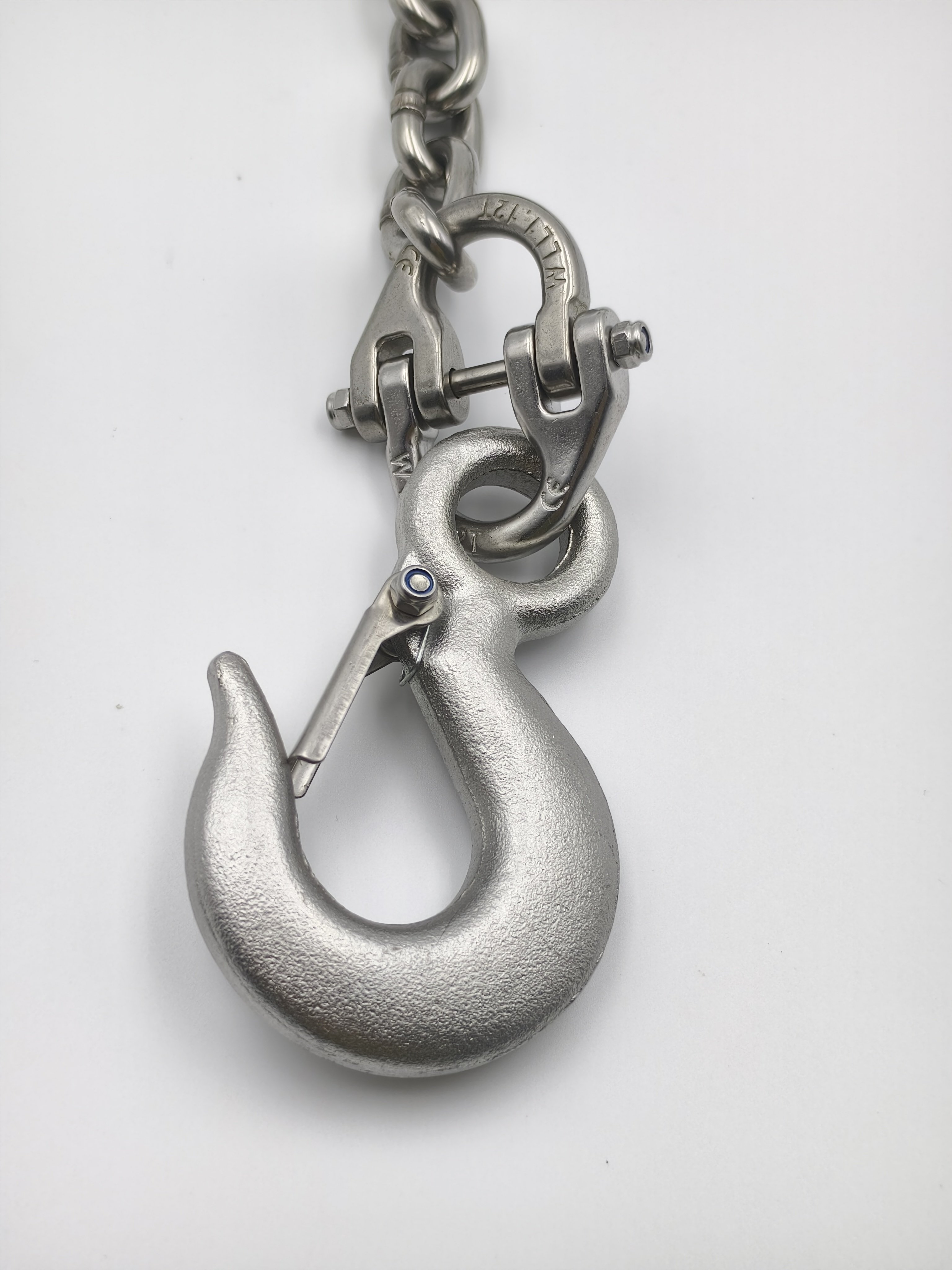

Hooks: self-locking above people, foundry hooks for wide lugs, shackles for tight pad-eyes. Maintain 10% throat clearance.

Shorteners: rated grab or clutch hooks adjust leg length; never knot or twist chain.

All components must match chain grade (e.g., G80 with G80, G100 with G100).

Chains lose strength at sharp edges. Use pads or spreaders, then record assumptions:

R≥2dR \ge 2d (link diameter dd) → full WLL.

R≈dR \approx d → 0.7 × WLL.

Sharp edge → 0.5 × WLL or redesign.

Inspect before each use, retire with measurable criteria:

Wear: average link diameter reduction ≥10%.

Stretch: five-link pitch growth ≥3%.

Hooks: throat opening >10% over nominal.

Any part: cracks, deep nicks, heat tint, stiff articulation, or lost ID.

1.Write load weight, mark center of gravity, and sketch four pick points.

2. <!--[endif]-->Open WLL table; size conservatively (treat as 3 legs).

3. <!--[endif]-->Fit master link in crane hook; confirm hook latch clearance.

4. <!--[endif]-->Attach hooks at lugs; confirm throat clearance and orientation.

5. <!--[endif]-->Equalize length with shorteners; cancel roll and pitch.

6. <!--[endif]-->Trial-lift a few centimeters; watch leg share and stability.

7. <!--[endif]-->Record tag numbers, dimensions, and observations.

When geometry grows complex, a 4 way chain rigging system delivers balance, stability, and traceable safety—then contact TOPONE CHAIN for certified four-leg assemblies designed to match your lifting plan.