Application Scenario 1: Engine Maintenance & Repair

Technical Specifications:

- Material: Heat-treated G80 alloy steel (8:1 safety factor)

- Temperature Resistance: Short-term exposure to 200°C (392°F)

- Surface Treatment: Electro-galvanized or hot-dip galvanized options

Purchasing Considerations:

- Engine Pulling Chains: Utilize designs with integrated safety latches to prevent accidental disengagement during overhead operations.

- Corrosion Protection: Utilize zinc-nickel coated chains for engine bays with oil/coolant exposure.

- Configuration:

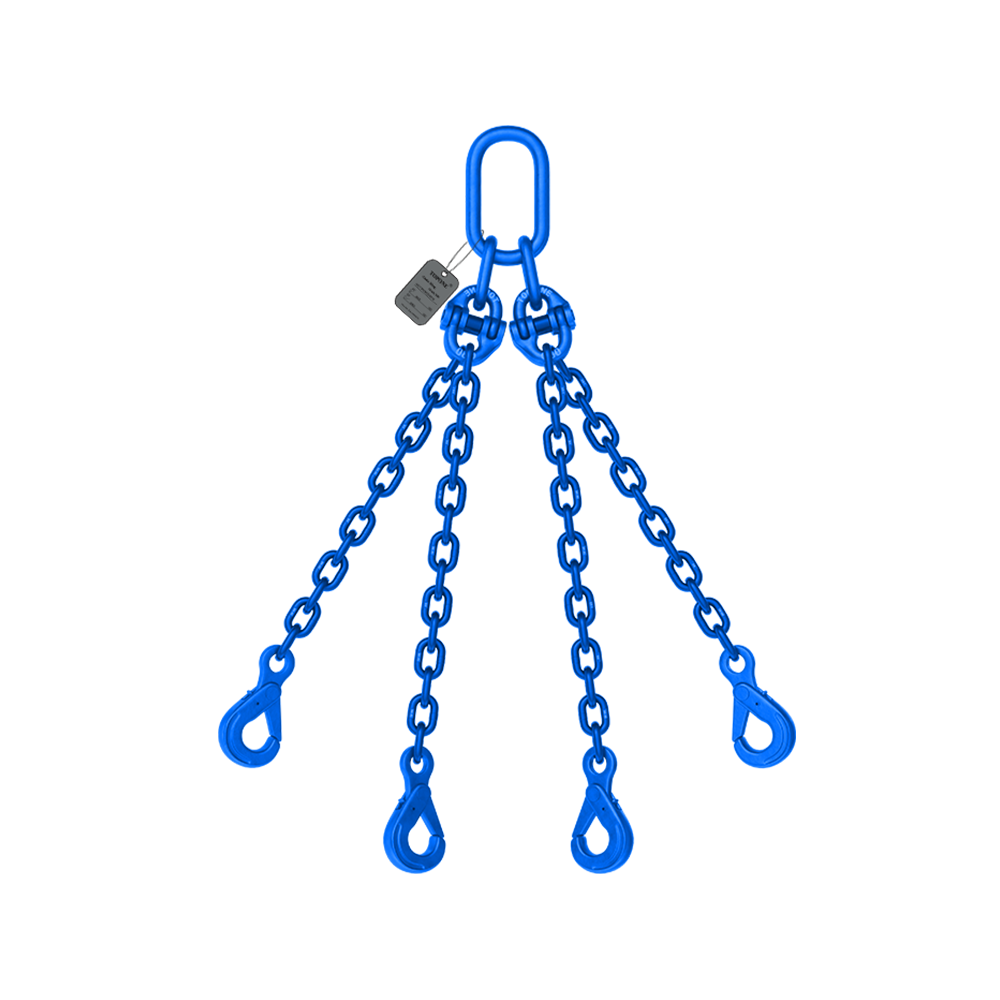

Single-leg chains for compact workshop spaces

4-leg sets for symmetrical lifting of diesel engines (2-5 ton capacity)

Application Scenario 2: Crane Operations

Technical Specifications:

- Leg Variations: 2/3/4-leg sets (±1% length tolerance)

- Certification: EN 818-4 compliant with permanent load tags

- Accessories: Swivel hooks with 360° rotation capacity

Operational Requirements

- Structural Lifting: Use 4-leg chain slings to transfer stress when lifting I-beams or prefab concrete parts.

- Chemical Environments: PVC-sleeved chains are acid fume resistant in petrochemical plants.

- Dynamic Loading: Verify shock load ratings (ASTM A391 certification must be present).

Application Scenario 3: Load Securing for Transportation

Technical Specifications:

Coating: 85μm hot-dip galvanizing (500+ hours salt spray resistance)

Hardware: Grade 70 ratchet binders with anti-slip teeth

Compliance: FMCSA (US) and ADR (EU) compliant

Implementation Tips:

Marine Transportation: Select self-draining chain designs to preclude saltwater accumulation.

Precise Loads: Use nylon-covered chains to preclude surface scratching on precision equipment.

Cold Climates: Confirm -40°C (-40°F) impact toughness (ISO 148 Charpy test).

Application Scenario 4: Heavy Equipment Relocation

System Components:

Main Chains: G100 alloy steel (10-ton WLL)

Load Balancers: Laser-etched calibration marks (±2% accuracy)

Safety Sensors: Overload alarms (trips at 110% WLL)

Best Practices:

Multi-Point Lifting: Maintain <90° angle between legs to prevent lateral overload.

Inspection Protocol:

Daily: Visual inspection + manual articulation test

Quarterly: Magnetic Particle Inspection (MPI)

Mixed Systems: Always rate capacity by weakest component.

Decision Framework: 5-Step Selection Process

1. Load Characterization

- Static vs. dynamic loads

- Center of gravity calculations

2. Environmental Factors

Condition\\tRecommended Solution

Chemical exposure\\t316 stainless steel chain

Abrasive particles\\tCarburized surface chain

UV radiation\\tUV-stable polymer coat

3. Certification Validation

- North America: ASME B30.9 + NRTL stamp

- Europe: CE + EN 818-series

- Global: ISO 9001 + third-party test certificates

4. Lifecycle Cost Analysis

- Initial procurement

- Maintenance annually (lubrication, inspection)

- Replacement threshold: Replace at 60% of replacement cost

5. Training Requirements

- ASME/OSHA compliance training

- Load angle calculation workshops

- Emergency release procedures

Critical Safety Reminders

- Chain Degradation Patterns:

80% of failures trace back to internal stress corrosion cracking – undetectable without NDT.

A 60° angle loads leg 1.15x; 90° angle doubles the load.

Maintain electronic records tracking each chain's service hours, max loads, and exposure to environment.