Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

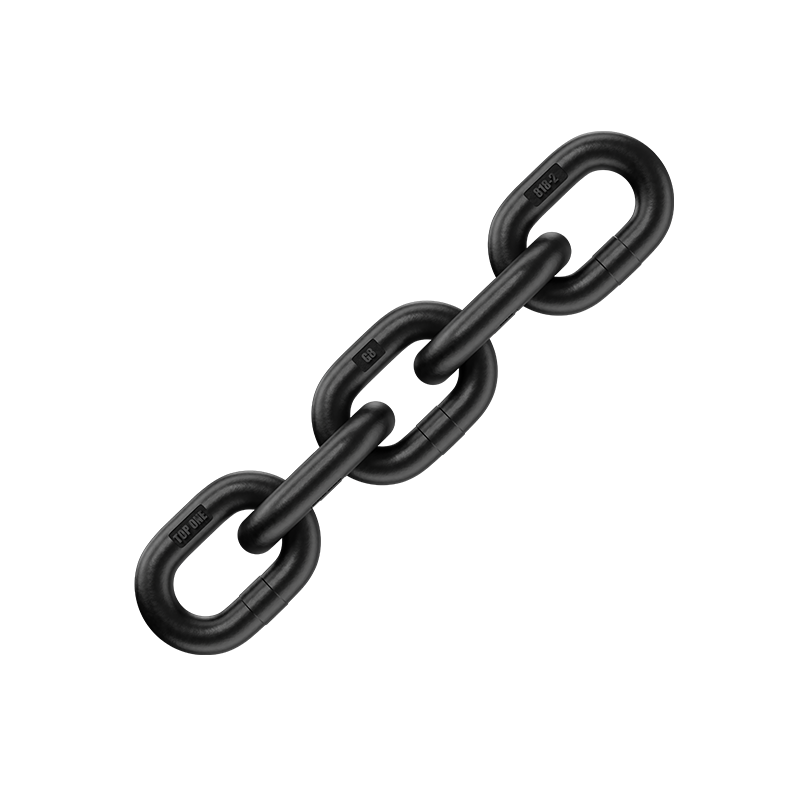

An alloy chain is the foundation of nearly every heavy-duty lifting system used in industrial environments. Engineered from quenched and tempered alloy steel, alloy chains provide exceptional tensile strength, resistance to fatigue, and high performance under extreme working conditions.

Because of these properties, alloy chain is the primary material used to manufacture alloy chain slings, alloy sling chain, and all types of alloy sling and chain assemblies for industrial lifting.

Although this page focuses on alloy chain, it is also structured to satisfy search intent related to chain sling, ensuring strong SEO visibility and relevance.

An alloy chain is a high-strength lifting chain manufactured from alloy steel—usually in Grades G80 or G100. Unlike ordinary industrial chains, alloy chains are specifically engineered for lifting and rigging applications that require strict performance and safety standards.

High tensile and breaking strength

Excellent resistance to wear and abrasion

Superior performance under shock loading

Functionality in extreme temperatures

Full compatibility with chain sling components

This makes alloy chain the preferred material for alloy chain slings and all major lifting applications.

https://www.lifting-chain.com/products/

https://www.lifting-chain.com/products/

When users search for chain sling, they are often looking for a complete lifting assembly. What they may not realize is that the alloy chain is the core structural component that determines sling strength, durability, and safety.

A chain sling cannot exist without a properly engineered alloy chain.

Alloy chain = the load-bearing backbone

Alloy chain slings = the assembled lifting solution

Alloy sling chain = the chain component within the sling system

By optimizing alloy chain quality, we elevate the performance of every chain sling configuration.

Standard lifting grade

Widely used in construction and manufacturing

Strong, reliable, cost-effective

Approximately 25% stronger than G80

Reduces sling weight

Preferred for offshore, heavy construction, and mining

Heat-resistant alloy chain

Corrosion-protected alloy chain

Customized sling chain for extreme industry use

These variants allow alloy chain to meet diverse chain sling requirements.

Alloy chain is used to produce single-leg, double-leg, three-leg, and four-leg alloy chain slings, as well as customized alloy sling and chain solutions.

Construction lifting

Steel fabrication

Mining & excavation

Shipbuilding & offshore structures

Heavy manufacturing

Transport & logistics

Precast concrete handling

In all these industries, alloy chain provides superior load security and long-term durability compared with wire rope or synthetic slings.

Feature | Alloy Chain | Ordinary Chain |

Strength | Extremely high | Low to medium |

Heat Resistance | Excellent | Limited |

Fatigue Resistance | High | Poor |

Suitable for Lifting? | YES (Certified) | NO (Unsafe) |

Certification | EN 818, ISO, CE, TÜV | No lifting certification |

Only alloy chain is legally and safely used for lifting. Ordinary chain is strictly prohibited in rigging.

Alloy chain slings outperform other lifting tools because they offer:

Highest durability among all sling types

Ability to withstand rough surfaces and sharp edges

Shock-load absorption

High operating temperature capability

Adjustable chain sling options for flexible geometry

Replaceable components (hooks, links, chain segments)

This makes alloy chain slings essential for industries requiring absolute reliability.

Google evaluates semantic relevance.

By presenting alloy chain as the material basis of all chain sling products, the page naturally fulfills the informational needs of users searching:

chain sling

alloy chain slings

alloy sling chain

alloy sling and chain

lifting chain systems

Thus, this article matches AND reinforces the chain sling topic, boosting SEO visibility.

Feature | Alloy Chain | Chain Sling |

Definition | High-strength alloy steel chain used as the core load-bearing material | A complete lifting assembly built using alloy chain + hooks + master link |

Function | Provides tensile strength and durability | Performs the actual lifting operation |

Components | Chain links only | Alloy chain, master link, connectors, end hooks |

Certification | Must meet EN 818, ISO, CE/TÜV | Must include chain + sling assembly certification |

Use Case | Manufacturing lifting equipment, rigging systems, chain sling production | Daily lifting tasks in construction, mining, logistics, etc. |

Flexibility | Can be cut, welded, or assembled into various sling configurations | Comes in fixed or adjustable forms (1-leg, 2-leg, 3-leg, 4-leg) |

Strength Role | Backbone of overall lifting capacity | Determines lifting method, geometry, and load control |

Maintenance | Inspect link wear, elongation, corrosion | Inspect hooks, master links, chain, angles, and tag compliance |

Suitability | Not a finished lifting tool by itself | Ready-to-use lifting solution |

➡ Summary:

Alloy chain = the raw strength

Chain sling = the complete lifting tool built from alloy chain

This comparison helps Google relate your alloy chain page to chain sling search intent.

An alloy chain is primarily used for manufacturing lifting equipment such as chain slings, hoist chains, rigging systems, and heavy-duty industrial connectors. Alloy chain provides the high tensile strength required for safe lifting.

No.

An alloy chain is just the chain material, while a chain sling is a complete lifting assembly built from alloy chain plus hooks and master links. A chain sling cannot exist without alloy chain.

Because alloy chain offers:

Superior strength-to-weight ratio

High resistance to heat and abrasion

Ability to handle shock loads

Long service life

These properties make it stronger and more durable than wire rope or synthetic slings.

The most common grades are:Both grades comply with international lifting standards such as EN 818.

5. Can alloy chain be used in high-temperature environments?

G80 alloy chain – standard industrial lifting

G100 alloy chain – higher capacity and efficiency

Both grades comply with international lifting standards such as EN 818.

Yes. Alloy chain can withstand high temperatures significantly better than synthetic slings. Foundries, steel mills, and hot-work industries rely heavily on alloy chain slings.

Consider:

Required Working Load Limit (WLL)

Chain grade (G80 or G100)

Diameter & lifting geometry

Hook type & sling configuration

Operating environment (heat, chemicals, corrosion)

Yes — only alloy chain that is certified (EN 818 / ISO / CE / TÜV) is approved for overhead lifting. Ordinary chain is prohibited.

Alloy chain slings are widely used in:

Construction

Mining

Offshore and shipbuilding

Logistics and transport

Manufacturing

Precast concrete and steel fabrication

Damaged alloy chain links must not be welded or repaired. If wear exceeds 10% or links are elongated, corroded, or cracked, the chain must be replaced.

TOPONE CHAIN® provides:

G80 & G100 certified alloy chain

Full traceability & test certificates

Advanced heat-treatment technology

Integration with our alloy chain sling systems

Global OEM/ODM capability

TOPONE CHAIN® manufactures both alloy chain AND complete alloy chain slings, ensuring perfect compatibility and traceability.

G80 & G100 alloy sling chain production

Nine automated heat-treatment and calibration lines

CE / TÜV / ISO9001 certified

Custom diameters and sling assemblies

Exported to 40+ countries

Professional OEM/ODM chain sling solutions

Our alloy chain forms the backbone of some of the world’s safest and most reliable lifting chain slings.

An alloy chain is more than a piece of steel—it is the high-strength component that enables safe, efficient, and long-lasting lifting operations.

Because it forms the core of every alloy chain sling, alloy sling chain, and industrial lifting solution, choosing a certified alloy chain is essential for safety and performance.

For high-quality alloy chain engineered for professional chain sling applications, TOPONE CHAIN® is your trusted global partner.