Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

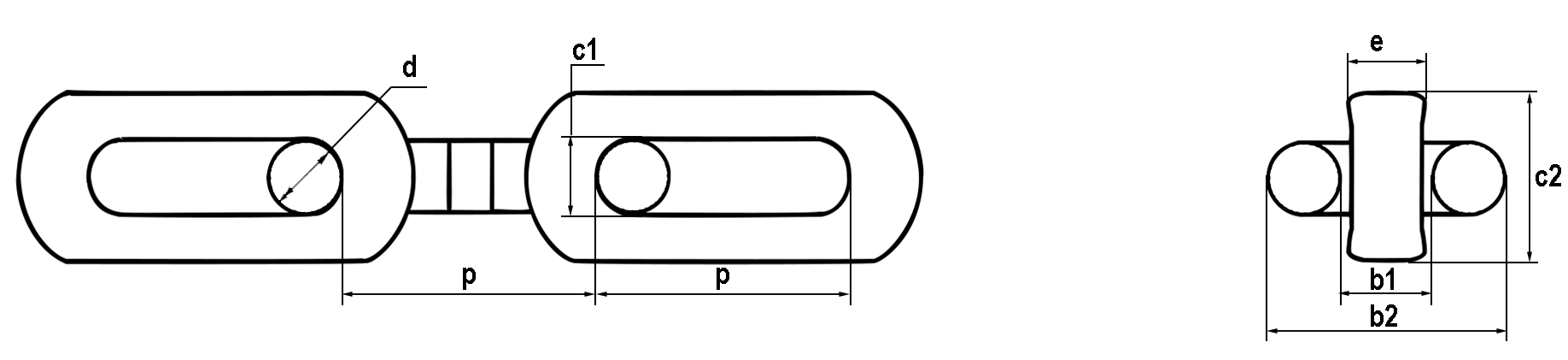

TOPONE® produces Flat link chains for use in continuous conveyors in mining Complies with DIN22255 dimensions and mechanical properties. Flat link mining chains may replace currently used round link chains of the same diameter, without the need of changing other assembly components.Especially suitable for Armored Face Conveyors, Beam Stage Loaders, road headers.

DIN 22255 flat link mining chains can replace the currently used DIN 22252 round link chains of the same diameter without changing other assembly parts. Compared with round link chains, flat link mining has a larger contact area, which reduces the risk of friction martensite and thus increases service life.In addition, since the outer height of the flat link mining chain (DIN22255) is smaller than the outer height of the round link mining chain (DIN22252), the flat link mining chain can be used as a diameter reduced by one order of magnitude. For example: Flat link chain 42x137 is of the height c2 = max 115 which corresponds to round link chain 38x137 b2 = max 121.

|

Chain Size |

Diameter |

Pitch |

Round Horizontal Link |

Flat Vertical Link |

e max |

Weight |

||

|

d x p (mm) |

d (mm) |

P (mm) |

b1 min, (mm) |

b2 max. (mm) |

c1 min. (mm) |

c2 max. (mm) |

(mm) |

(kg) |

|

26x92 |

26 ±0.8 |

92 ±0.9 |

30.1 |

87 |

30 |

75 |

30.0 |

13.7 |

|

30x108 |

30 ±0.9 |

108 ±1.1 |

34.1 |

99 |

34 |

87 |

34.0 |

18.0 |

|

34x126 |

34 ±1.0 |

126 ±1.3 |

38.1 |

111 |

38 |

99 |

38.0 |

22.7 |

|

38x126 |

38 ±1.1 |

126 ±1.3 |

42.1 |

123 |

42 |

111 |

42.0 |

30.1 |

|

38x137 |

38 ±1.1 |

137 ±1.4 |

42.1 |

123 |

42 |

111 |

42.0 |

29.0 |

|

38x146 |

38 ±1.1 |

146 ±1.5 |

42.1 |

123 |

42 |

111 |

42.0 |

27.6 |

|

42x137 |

42 ±1.1 |

137 ±1.4 |

48.6 |

139 |

46 |

115 |

48.5 |

37.0 |

|

42x146 |

42 ±1.1 |

146 ±1.5 |

48.6 |

139 |

46 |

115 |

48.5 |

36.0 |

|

48x152 |

48 ±1.4 |

152 ±1.5 |

62 |

163 |

54 |

127 |

56.0 |

47.0 |

|

Mechanical Properties |

||||||

|

Chain Size d x p |

Chain Grade |

Test Force |

Breaking Force min. |

Elongation at test force max. |

Elongation at breaking force min. |

Fatigue Resistance min. |

|

(mm) |

(KN) |

(KN) |

(%) |

(%) |

(cycles) |

|

|

26x92 |

C |

637 |

850 |

1.6 |

11 |

70000 |

|

C++ |

700 |

970 |

1.6 |

14 |

90000 |

|

|

D |

740 |

1060 |

1.4 |

11 |

90000 |

|

|

30x108 |

C |

848 |

1130 |

1.6 |

11 |

70000 |

|

C++ |

950 |

1280 |

1.6 |

14 |

90000 |

|

|

D |

990 |

1400 |

1.4 |

11 |

90000 |

|

|

34x126 |

C |

1090 |

1450 |

1.6 |

11 |

70000 |

|

C++ |

1200 |

1650 |

1.6 |

14 |

90000 |

|

|

D |

1270 |

1800 |

1.4 |

11 |

90000 |

|

|

38x126 |

C |

1360 |

1820 |

1.6 |

11 |

70000 |

|

C++ |

1500 |

2040 |

1.6 |

14 |

90000 |

|

|

D |

1590 |

2270 |

1.4 |

11 |

90000 |

|

|

38x137 |

C |

1360 |

1820 |

1.6 |

11 |

70000 |

|

C++ |

1500 |

2040 |

1.6 |

14 |

90000 |

|

|

D |

1590 |

2270 |

1.4 |

11 |

90000 |

|

|

38x146 |

C |

1360 |

1820 |

1.6 |

11 |

70000 |

|

C++ |

1500 |

2040 |

1.6 |

14 |

90000 |

|

|

D |

1590 |

2270 |

1.4 |

11 |

90000 |

|

|

42x137 |

C |

1660 |

2220 |

1.6 |

11 |

70000 |

|

C++ |

1800 |

2500 |

1.6 |

14 |

90000 |

|

|

D |

1940 |

2770 |

1.4 |

11 |

90000 |

|

|

42x146 |

C |

1660 |

2220 |

1.6 |

11 |

70000 |

|

C++ |

1800 |

2500 |

1.6 |

14 |

90000 |

|

|

D |

1940 |

2770 |

1.4 |

11 |

90000 |

|

|

48x152 |

C |

1900 |

2900 |

1.6 |

11 |

70000 |

|

C++ |

2350 |

3255 |

1.6 |

14 |

90000 |

|

|

D |

2530 |

3600 |

1.4 |

11 |

90000 |

|

!This product is not recommended for overhead lifting.

!Any surface coating will affect the mechanical properties of the chain.Please ask staff for details.

!Fatigue resistance T [cycles] and impact force KV [J] according to DIN 22255 standard

!Enhanced performance chains are not recommended for use in harsh, corrosive environments, as pitting and friction martensite may lead to operational failures.

We follow standards:

DIN 17115

Acc. to DIN 22255 or MT/T 929

DIN 50100

DIN EN ISO 148

DIN EN ISO 6506

Optional surface treatment: natural black, powder coating, black electrophoresis, electro-galvanizing, hot-dip galvanizing, Dacromet.

Ambient temperature during use:

Min.: -40 ℃

Max.: 200 ℃

If the application scenario exceeds or is lower than the recommended operating temperature, please consult the staff to see if it is feasible.