Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

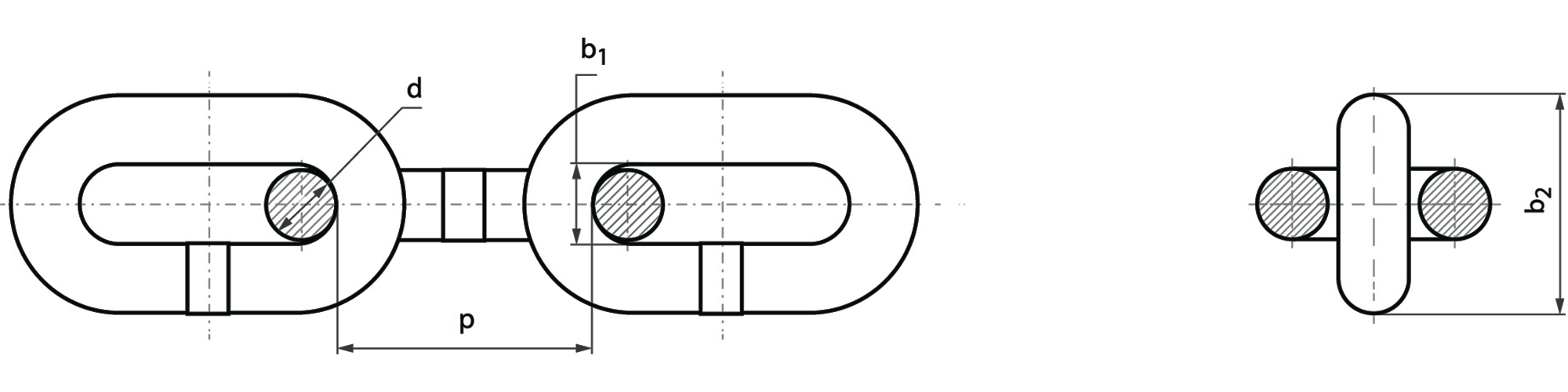

TOPONE® can produce medium ring steel chains in accordance with DIN 764 dimensions, pitch 3.5D. Grade 3, Grade 4, Grade 6, Grade 8, calibrated and tested. Surface hardening is also available, up to 64HRC. Especially suitable for industrial conveyor chains and wear chains.

Chains according to this standard are mainly used as traction means in continuous conveyors. They can be sold in bulk or in drums. All chains are calibrated. This product is strictly prohibited from being used for overhead lifting.

|

Diameter d |

Pitch p |

Inside b1 (Min) |

Working Load Limited |

Proof Load |

Min Breaking Load |

Weight per Meter |

|

(mm) |

(mm) |

(mm) |

(kg) |

(KN) |

(KN) |

(Kg/m) |

|

4 ±0.2 |

16 +0.3/-0.2 |

5 |

200 |

5 |

8 |

0.31 |

|

5 ±0.2 |

18 +0.4/-0.2 |

7 |

320 |

8 |

12.5 |

0.51 |

|

6 ±0.2 |

21 +0.5/-0.2 |

8 |

400 |

10 |

16 |

0.74 |

|

8 ±0.2 |

28 +0.5/-0.3 |

11 |

800 |

20 |

32 |

1.31 |

|

10 ±0.3 |

35 +0.6/-0.3 |

14 |

1250 |

32 |

50 |

2.00 |

|

12 ±0.3 |

42 +0.6/-0.3 |

16 |

1800 |

45 |

75 |

2.98 |

|

13 ±0.1 |

45 +0.7/-0.4 |

18 |

2000 |

50 |

80 |

3.50 |

|

16 ±0.5 |

56 +0.9/-0.5 |

22 |

3200 |

80 |

125 |

5.20 |

|

18 ±0.8 |

63 +1.0/-0.5 |

24 |

4000 |

100 |

160 |

6.50 |

|

20 ±1.0 |

70 +1.1/-0.6 |

27 |

5000 |

125 |

200 |

8.20 |

|

23 ±1.2 |

80 +1.3/-0.7 |

31 |

6300 |

160 |

250 |

11.00 |

|

26 ±1.3 |

91 +1.5/-0.5 |

35 |

8000 |

200 |

320 |

14.00 |

|

28 ±1.4 |

98 +1.6/-0.9 |

36 |

10000 |

250 |

400 |

16.50 |

|

30 ±1.5 |

105 +1.7/-0.9 |

39 |

11200 |

280 |

450 |

19.00 |

|

33 ±1.7 |

115 +1.9/-1.0 |

43 |

12500 |

320 |

500 |

22.50 |

!This product is strictly prohibited from being used for overhead lifting.

!Any surface coating will affect the mechanical properties of the chain.Please ask staff for details.

We follow standards:

DIN 17115

DIN 764

Optional surface treatment: natural black, powder coating, black electrophoresis, electro-galvanizing, hot-dip galvanizing, Dacromet.

Chain should be inspected every six months for cracks, gouges, wear, elongation, nicks, and suitability.

Chain performance can be effected by excessive temperatures or exposure to chemically active environments such as acids, corrosive liquids or fumes.

When mixing chain and components such as hooks and links, all should be rated at the work load limit of the lowest rated component or chain.

Ambient temperature during use:

Min.: -40 ℃

Max.: 200 ℃

If the application scenario exceeds or is lower than the recommended operating temperature, please consult the staff to see if it is feasible.