Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

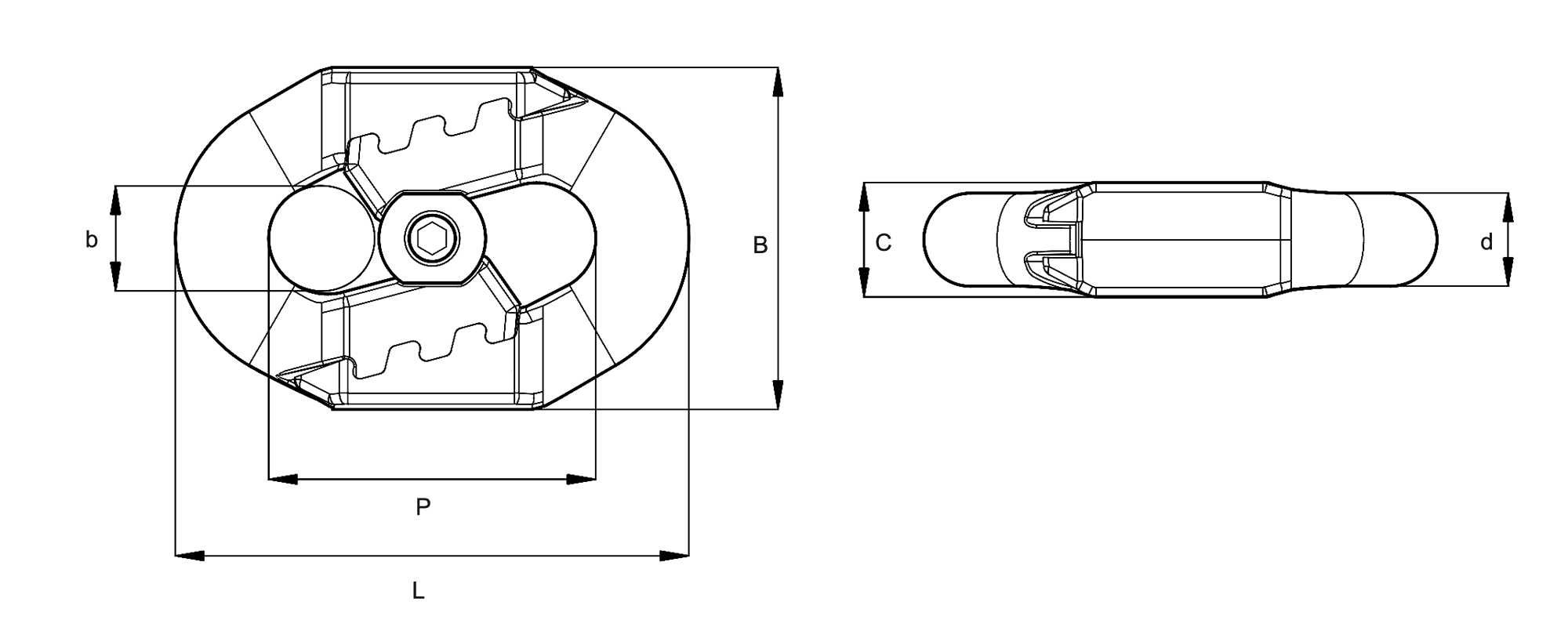

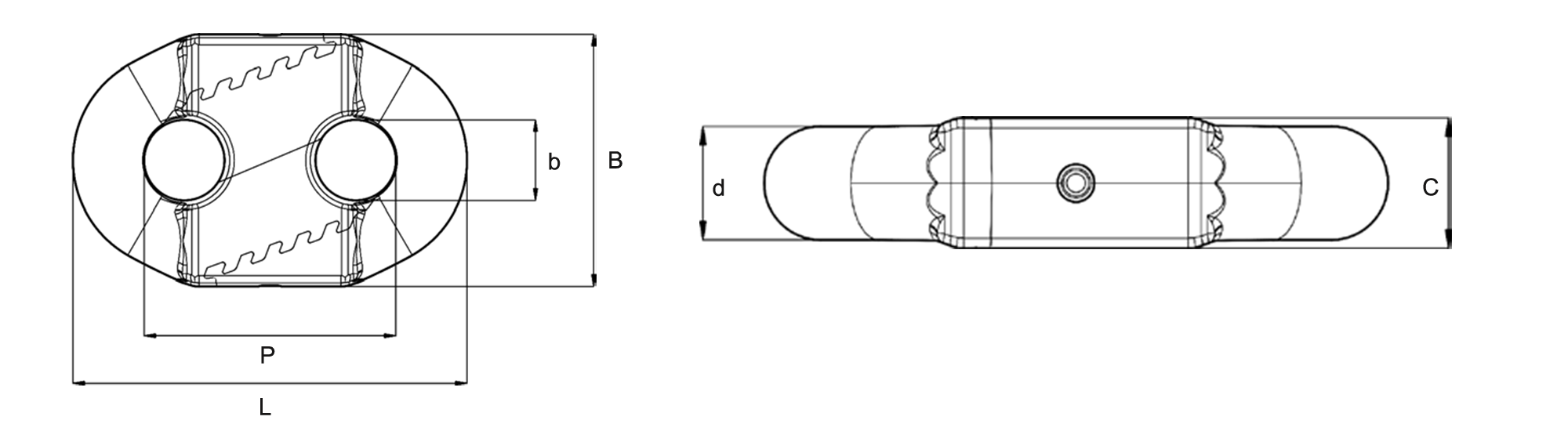

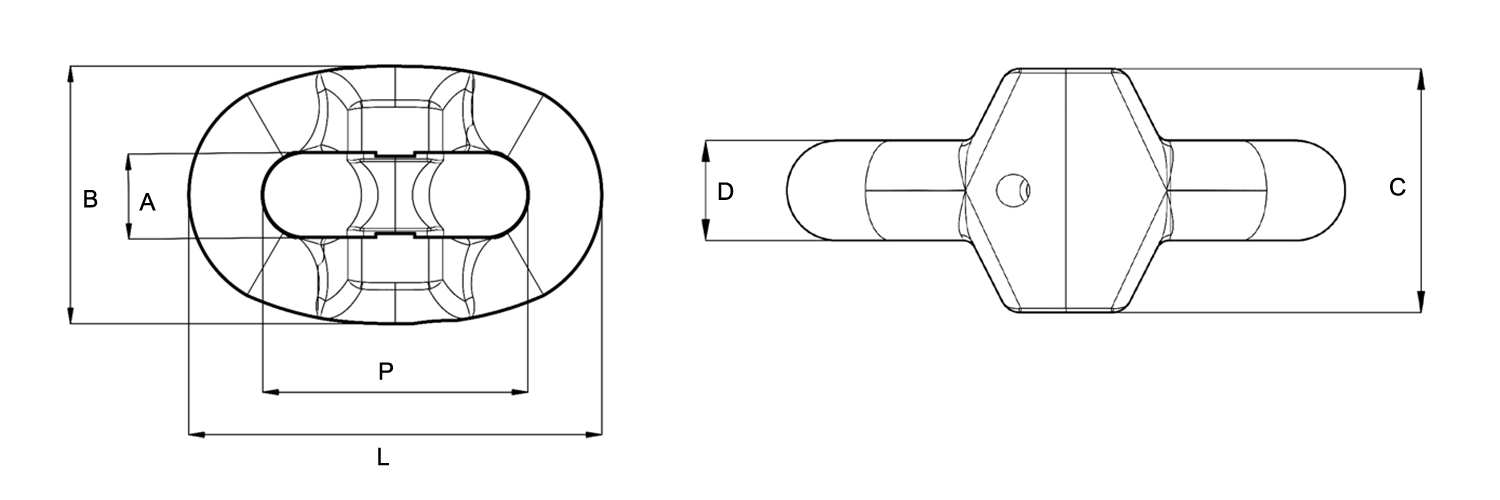

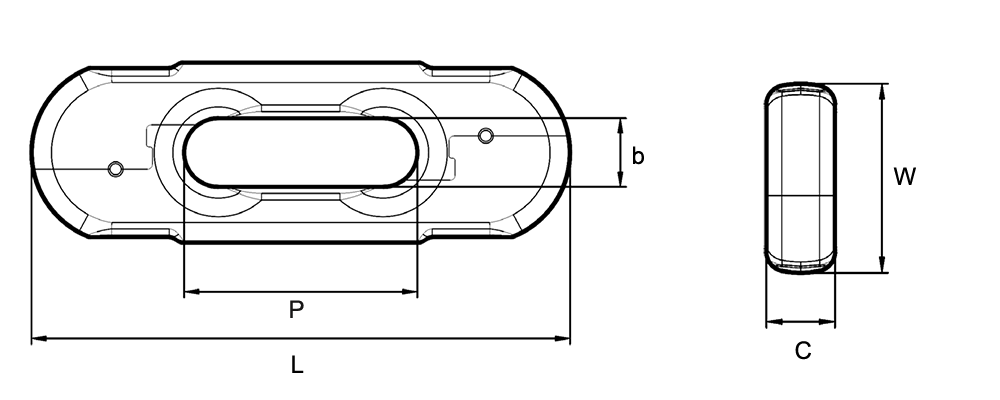

TOPONE® can produce mining connection links that meet DIN 22258 standards. We can provide four models of products. A1 model: Rapid Connecting Link, A2 model: Flat Serrated Chain Link, A3 model: Flat Chain Link, A4 model: Vertical Chain Link. All connection links are forged.

DIN 22258 link chains produced by TOPONE® can be used for DIN 22252 mining round link chains and DIN 22255 mining flat link chains. The production process adopts forging + CNC cutting + heat treatment. The material is high NI, CR, MO high-quality alloy steel. 100% tested before leaving the factory.Carburizing is also available.

|

A1-Rapid Connecting Link |

||||||||||||

|

Chain Size |

d |

P |

L |

b |

B |

C |

Proof Load MPL |

Breaking Load MBL |

Fatigue Resistance |

Weight |

||

|

d x p |

(mm) |

(mm) |

max. |

min. |

max. |

max. |

DIN |

D |

DIN |

D |

(cycles) |

(kg) |

|

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(KN) |

(KN) |

(KN) |

(KN) |

||||

|

18x64 |

18 |

64 |

102 |

20 |

72 |

24 |

305 |

420 |

361 |

480 |

40000 |

0.7 |

|

22x86 |

22 |

86 |

132 |

24 |

84 |

28 |

456 |

640 |

540 |

715 |

40000 |

1.3 |

|

24x86 |

24 |

86 |

136 |

26 |

85 |

30 |

543 |

760 |

642 |

845 |

40000 |

1.5 |

|

26x92 |

26 |

92 |

146 |

29 |

96 |

33 |

637 |

830 |

754 |

1000 |

70000 |

2.0 |

|

30x108 |

30 |

108 |

170 |

33 |

109 |

36 |

848 |

1100 |

1000 |

1330 |

70000 |

3.0 |

|

34x126 |

34 |

126 |

196 |

37 |

121 |

41 |

1090 |

1400 |

1290 |

1690 |

70000 |

4.3 |

|

38x126 |

38 |

126 |

204 |

41 |

137 |

46 |

1360 |

1770 |

1610 |

2120 |

70000 |

5.4 |

|

38x137 |

38 |

137 |

215 |

41 |

134 |

46 |

1360 |

1770 |

1610 |

2120 |

70000 |

5.8 |

|

38x146 |

38 |

146 |

224 |

41 |

137 |

46 |

1360 |

1770 |

1610 |

2120 |

70000 |

6.1 |

|

42x146 |

42 |

146 |

235 |

45 |

150 |

53 |

1660 |

2160 |

1970 |

2560 |

70000 |

7.4 |

|

PS:Can be used to connect vertical or horizontal mining round link chains | ||||||||||||

|

A2-Flat Serrated Chain Link |

|||||||||

|

Chain Size |

d |

P |

L |

b |

B |

C |

Breaking Load |

Fatigue Resistance |

Weight |

|

d x p |

(mm) |

(mm) |

max. |

min. |

max. |

max. |

MBL |

(cycles) |

(kg) |

|

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(KN) |

||||

|

18 x 64 |

18 ±0.6 |

64 ±0.6 |

102 |

20 |

66 |

23 |

410 |

40000 |

0.65 |

|

22 x 86 |

22 ±0.7 |

86 ±0.9 |

132 |

24 |

85 |

27 |

610 |

40000 |

1.2 |

|

26 x 92 |

26 ±0.8 |

92 ±0.9 |

146 |

28 |

97 |

33 |

850 |

40000 |

2 |

|

30 x 108 |

30 ±0.9 |

108 ±1.1 |

170 |

32 |

109 |

36 |

1130 |

40000 |

2.9 |

|

34 x 126 |

34 ±1.0 |

126 ±1.3 |

196 |

36 |

121 |

41 |

1450 |

40000 |

4.3 |

|

38 x 137 |

38 ±1.1 |

137 ±1.4 |

215 |

40 |

134 |

46 |

1630 |

40000 |

5.8 |

|

PS:Can be used to connect vertical or horizontal mining round link chains | |||||||||

|

A3-Flat Chain Link |

|||||||||

|

Chain Size |

D |

P |

C |

A |

L |

B |

Breaking Load |

Fatigue Resistance |

Weight |

|

d x p |

(mm) |

(mm) |

max. |

min. |

max. |

max. |

MBL |

(cycles) |

(kg) |

|

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(KN) |

||||

|

26 x 92 |

26 ±0.8 |

92 ±0.9 |

65 |

30 |

148 |

95 |

1050 |

100000 |

2.5 |

|

30 x 108 |

30 ±0.9 |

108 ±1.1 |

75 |

35 |

170 |

109 |

1400 |

100000 |

4 |

|

34 x 126 |

34 ±1.0 |

126 ±1.3 |

85 |

36 |

196 |

120 |

1800 |

100000 |

6.4 |

|

38 x 126 |

38 ±1.1 |

126 ±1.3 |

94 |

43 |

204 |

134 |

2220 |

100000 |

7 |

|

38 x 137 |

38 ±1.1 |

137 ±1.3 |

94 |

43 |

215 |

134 |

2220 |

100000 |

7.6 |

|

42 x 146 |

42 ±1.3 |

146 ±1.5 |

105 |

47 |

232 |

148 |

2700 |

100000 |

10.7 |

|

48 x 152 |

48 ±1.5 |

152 ±1.5 |

118 |

54 |

249 |

170 |

3550 |

100000 |

14.4 |

|

PS:The flat link must be installed horizontally to cooperate with the sprocket made according to DIN22256 standard | |||||||||

|

A4-Vertical Chain Link |

|||||||||

|

Chain Size |

W |

P |

b |

C |

L |

Breaking Load |

Fatigue Resistance |

Weight |

|

|

d x p |

max. |

(mm) |

Tolerance |

min. |

max. |

max. |

MBL |

(cycles) |

(kg) |

|

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(KN) |

|||

|

22 x 86 |

62 |

86 |

±0.9 |

26 |

25 |

186 |

680 |

70000 |

1.45 |

|

26 x 92 |

75 |

92 |

±0.9 |

28 |

28 |

213 |

960 |

70000 |

2.28 |

|

30 x 108 |

87 |

108 |

±1.1 |

32 |

32 |

241 |

1270 |

70000 |

3.4 |

|

34 x 126 |

98 |

126 |

±1.3 |

36 |

36 |

292 |

1700 |

100000 |

5.02 |

|

38 x 126 |

110 |

126 |

±1.3 |

40 |

40 |

290 |

1900 |

100000 |

6 |

|

38 x 137 |

110 |

137 |

±1.4 |

40 |

40 |

302 |

1900 |

100000 |

6.6 |

|

42 x 146 |

114 |

146 |

±1.5 |

44 |

44 |

330 |

2300 |

100000 |

8.2 |

|

48 x 144 |

127 |

144 |

±1.5 |

51 |

56 |

334 |

2900 |

100000 |

10.36 |

|

48 x 152 |

127 |

152 |

±1.5 |

53 |

56 |

331 |

2900 |

100000 |

11 |

|

52 x 170 |

127 |

170 |

±1.5 |

57 |

64 |

373 |

3700 |

100000 |

14.8 |

|

56 x 187 |

131 |

187 |

±1.5 |

60 |

65 |

411 |

4300 |

100000 |

15 |

|

60 x 181 |

137 |

181 |

±1.5 |

64 |

70 |

452 |

5000 |

100000 |

20 |

|

PS:The vertical link must be installed vertically to cooperate with the sprocket made according to DIN22256 standard | |||||||||

!This product is not for overhead lifting.

!Any surface coating will affect the mechanical properties of the chain.Please ask staff for details.

!Fatigue resistance T [cycles] and impact force KV [J] according to DIN 22258 standard

!Enhanced performance connecting link not recommended for use in harsh, corrosive environments, as pitting and friction martensite may lead to operational failures.

!Ensure the cleanliness of the mounting surface and locking surface.

!Regular inspection for wear and damage.

!It is not allowed to insert other accessories between the two chainrings.

!Inspection is conducted every three months or after 1 million tons of coal is transported.

!Insert the two half rings into the chain and buckle them together, and drive in the middle fixing pin to prevent them from loosening.

We follow standards:

DIN 17115

Acc. to DIN 22258-1,DIN 22258-2,DIN 22258-3,PN-G-46705,MT/T 99

DIN 50100

DIN EN ISO 148

DIN EN ISO 6506

Optional surface treatment: natural black, powder coating, black electrophoresis, electro-galvanizing, hot-dip galvanizing, Dacromet.

Ambient temperature during use:

Min.: -40 ℃

Max.: 200 ℃

If the application scenario exceeds or is lower than the recommended operating temperature, please consult the staff to see if it is feasible.