Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

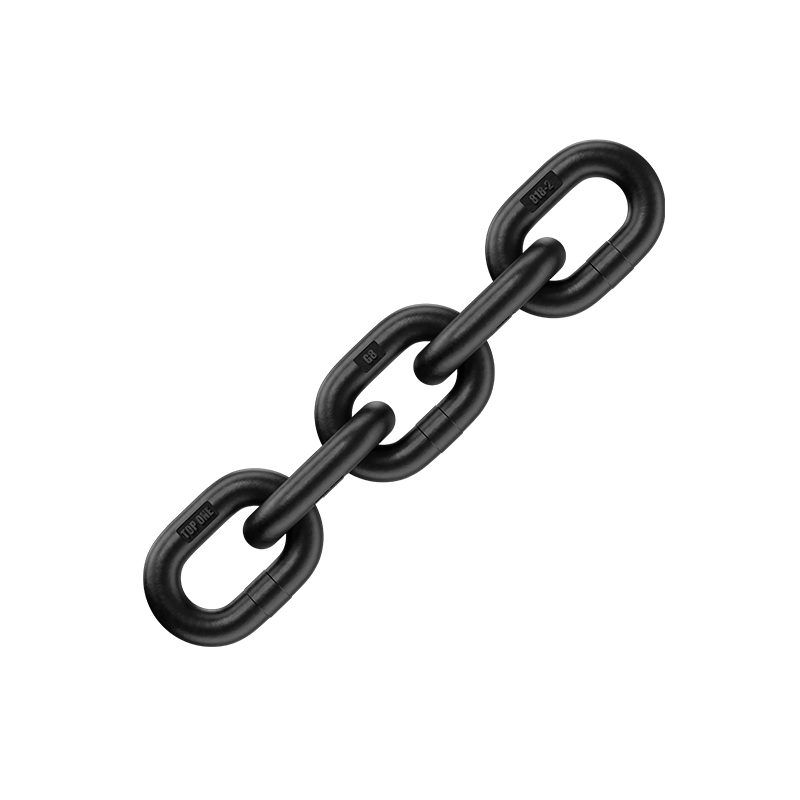

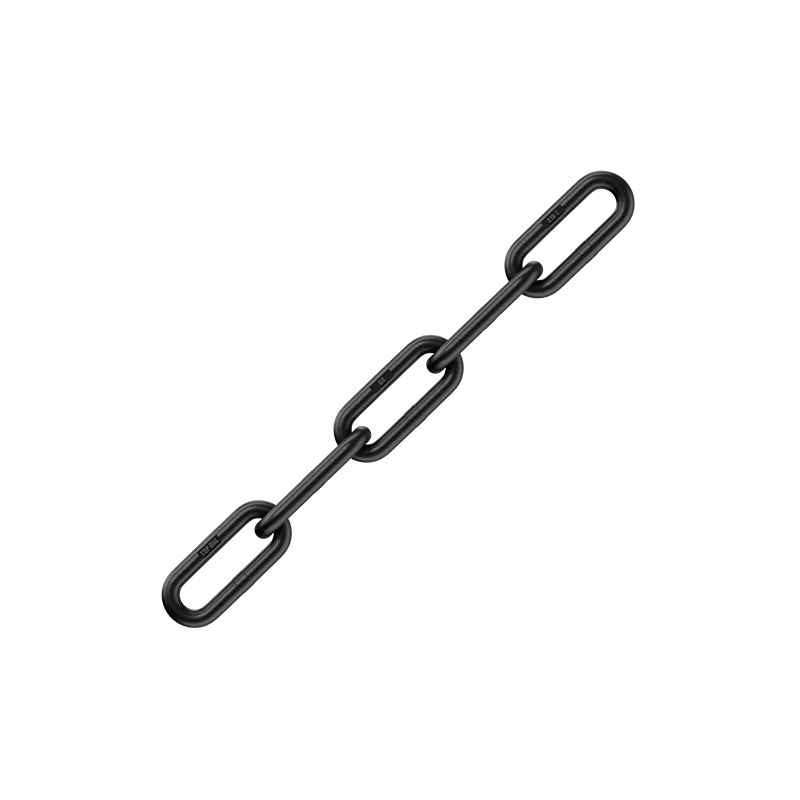

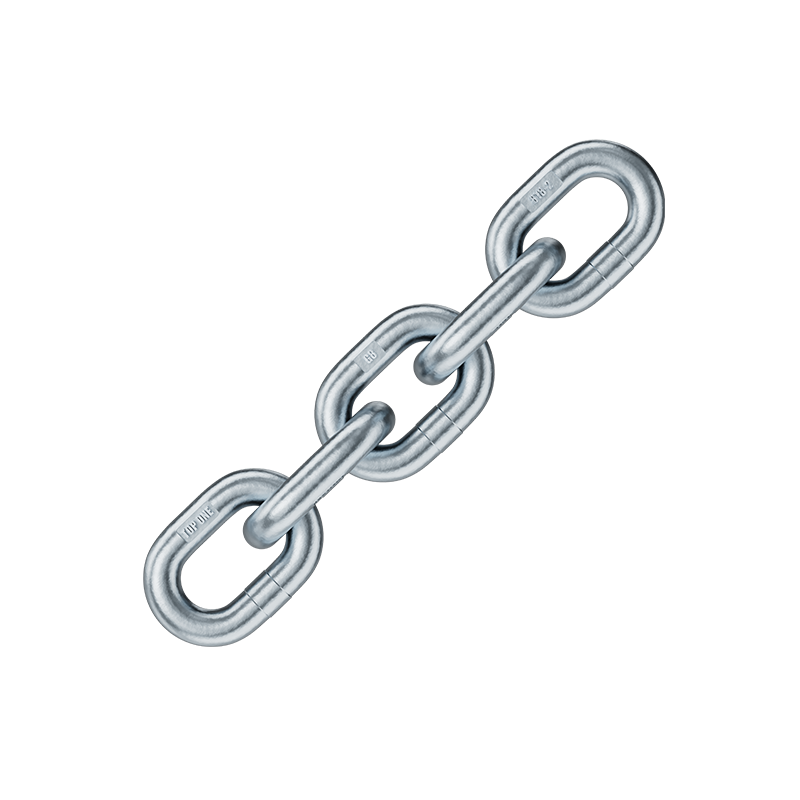

G80 alloy chains owe their strength to medium-carbon steel (C45 grade) heat-treated to provide tensile strength of 80,000 psi. The production involves heating the steel to 850°C (1,562°F) and rapid oil quenching. This produces a hard microstructure resistant to deformation when subjected to heavy loads. In contrast to conventional chains, G80 types are tempered at 450°C to optimize hardness and flexibility, thus suitable for dynamic lifting applications.

One industry practice error is using uncertified replacements for lifting chains with hooks. Original G80 chains display sequential heat treatment marks at every 12 inches (30 cm) and ASME B30.9 certifying stamp marks.

Correct setup during container lifting with chains prevents overload conditions. For typical 20-foot ISO containers (max gross weight 30,480 kg), four-leg chain slings are typical. Chain angles, though, considerably influence load distribution:

It is reported that a port operator in Rotterdam reduced chain failures by 58% after switching from 60° to 45° configurations, using Grade 80 lifting hooks and chain assemblies.

Compatibility of G80 chains with proper hooks requires consideration of three important dimensions:

As an example, a 10mm G80 chain will need:

Improper components like those used within ad-hoc rigging systems account for 34% of all lifting incidents according to OSHA statistics.

As lifting strops gain popularity for light-duty applications, G80 chains offer distinct advantages in harsh environments:

However, synthetic slings remain ideal for delicate surfaces like polished equipment or glass panels where chain marks can cause damage.

Field experience from mining operations shows chains that run in wet conditions require:

One German automaker replaced Grade 70 chains with G80 alloy types on their 10-ton foundry cranes and realized:

A North Sea drilling platform used G80 chains, zinc-nickel coated (ISO 9227 Class 5), and had a service life of 9 to 22 months in constant exposure to saltwater.

Xintai Taida Mirso Co., LTD delivers G80 alloy chains manufactured in our 15,000㎡ ISO 9001-certified facility, combining robotic welding precision (0.1mm accuracy) with ASME B30.9 compliance. With 9 automated lines producing 500,000+ chains annually, we serve 30+ countries across mining, maritime, and construction sectors.

Why Partner With Us?

✓ Certified Quality – EN 818-2 & DNVGL-OS-E304 certified

✓ Custom Solutions – Chains for extreme temps (-40°C to 400°C) and corrosive environments

✓ Global Support – 48-hour technical response & DDP shipping

Limited Offer: First orders over $3,000 receive free load calculation software.

Contact Our Engineers Today:

? [email protected]

? +86 18766656705

Serving global clients since 2008 with 98% on-time delivery rate.