Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

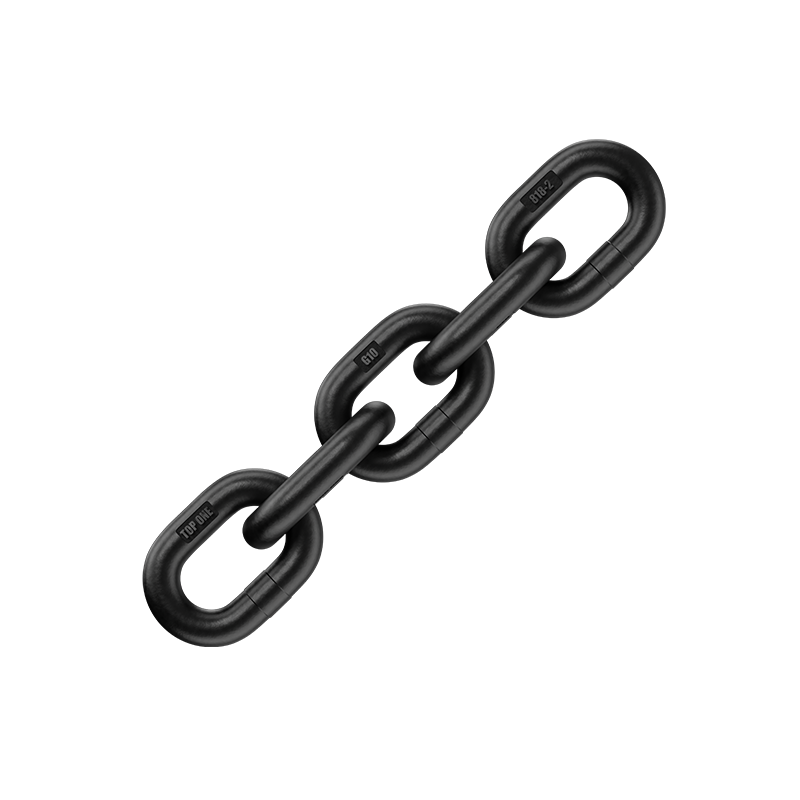

When lifting heavy machinery or counterbalancing unbalanced loads, the right size of chain and rigging set-up is crucial. G80 lifting chains constructed from heat-treated alloy steel give unmatched strength to construction, shipping, and logistics sectors. You might need a 10mm lifting chain for medium weight or a 4-point lifting chain for stability. TOPONE®'s qualified solutions ensure efficiency and safety.

Let's compare chain sizes like 1/2 lifting chain, 1/4 lifting chain, and 3/8 x 20 G70 chain, and observe how 4-way chain rigging optimizes complex lifts.

TOPONE® G80 chains utilize chromium, nickel, and molybdenum-enriched alloy steel, heat-treated to a 4:1 safety factor. They outperform 3/8 x 20 G70 chain in tensile strength (32,000 lbs break point) and resist abrasion, corrosion, and extreme temperatures (-40°C to 200°C).

Electroplated or galvanized coatings protect chains in marine, mining, and chemical-intensive environments. A 10mm powder-coated lifting chain, for example, resists saltwater and UV conditions.

10mm Lifting Chain: Medium-Duty Utility

WLL: ~3,200 kg (7,055 lbs).

Applications: Machinery securing, hoist integration, or as a replacement for 3/8 load chains in trucking.

Characteristics: Resilient yet pliable for repetitive lifts.

1/2" & 1/4" Lifting Chains: Precision for Lighter Loads

1/2 lifting chain: Handles ~4,500 kg (9,920 lbs) for construction rigging.

1/4 lifting chain: Ideal for light applications like equipment securing in warehouses.

3/8 x 20 G70 vs G80 Chains

While the 3/8 x 20 G70 chain is suitable for light loads, G80 chains offer 25% higher WLL and increased resistance to shock loads.

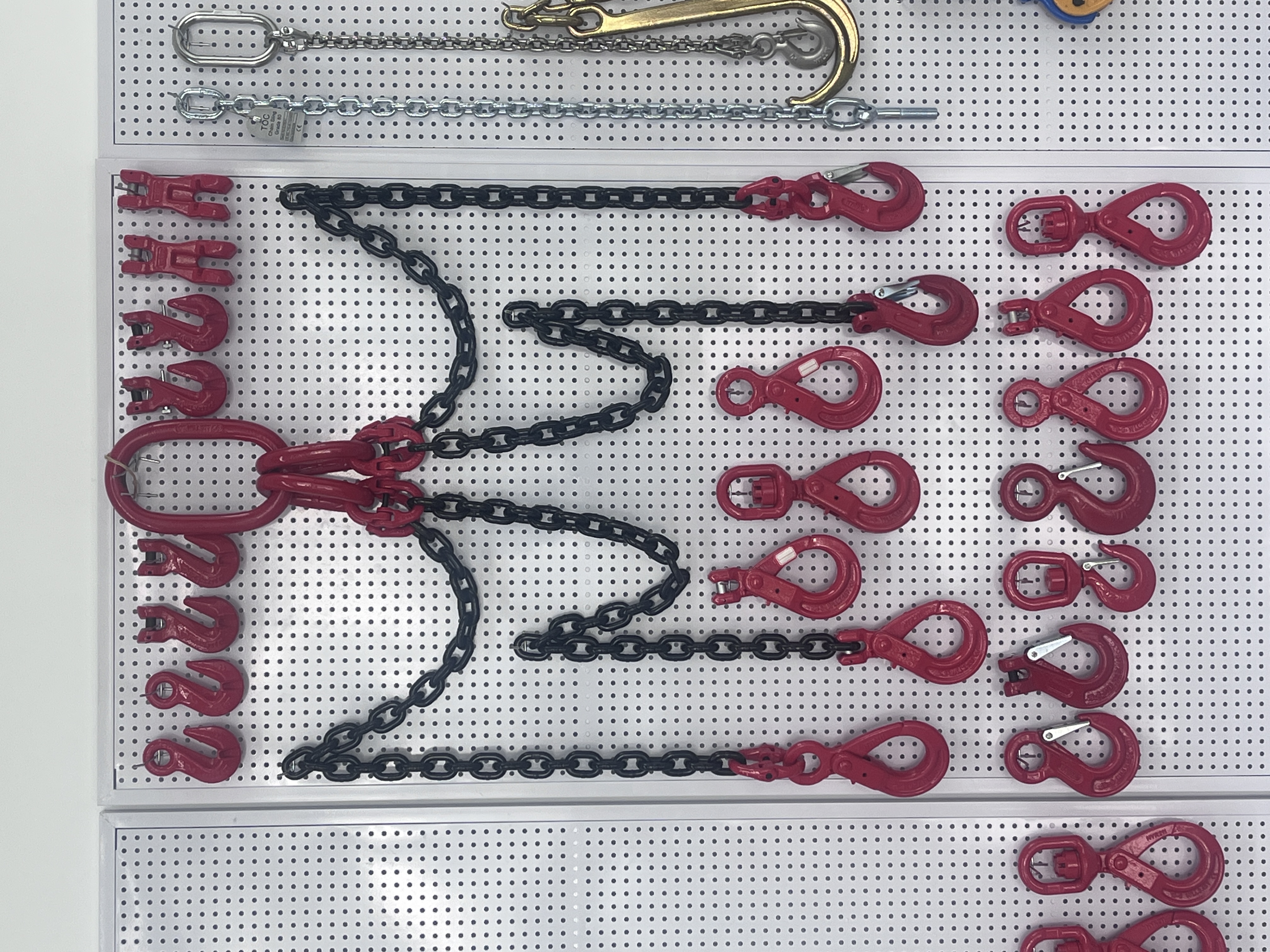

A 4-point lifting chain distributes weight uniformly across symmetrical loads like concrete slabs or steel coils. This reduces wear on individual legs and minimizes sway.

Optimizing 4-Way Chain Rigging Setups

4-way lifting chains with adjustable hooks and spreader bars adapt to irregular shapes. TOPONE®’s kits include Grade 80 alloy steel chains and OSHA-compliant rigging accessories.

Match Chain to Load: Never overload WLL (25% of break strength).

Inspect Regularly: Inspect 1/2 lifting chains for cracks or elongation; replace broken links.

Use Load Arrestors: Prevent shock loads in 4-way chain rigging configurations.

Train Teams: Ensure workers are aware of ASME B30.9 and EN818-2 standards.

For high-risk applications, apply chains with TOPONE®'s safety harnesses.

Certified Quality: Meets EN818-2, ASTM A973, and ISO 9001.

Custom Sizes: 10mm, 1/4", 1/2", and 4-way adjustable legs lifting chains.

Competitive Pricing: Bulk orders of 4-point lifting chain kits at discounted prices.

12-Month Warranty: Consistent performance in extreme conditions.

Browse our G80 chain catalog or request quotes.