Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

Used for ship deck lashing and log lashing. It is still tested with 2.5 times the safe load before leaving the factory, but we do not recommend it for lifting work. It can be sold with various hooks and chain tensioners.

TOPONE® lashing chains, for lashing extremely heavy cargo on ships and timber trucks automatic lashing devices.Suitable for lashing and fixing of ocean-going transport engineering equipment. 100% tested.

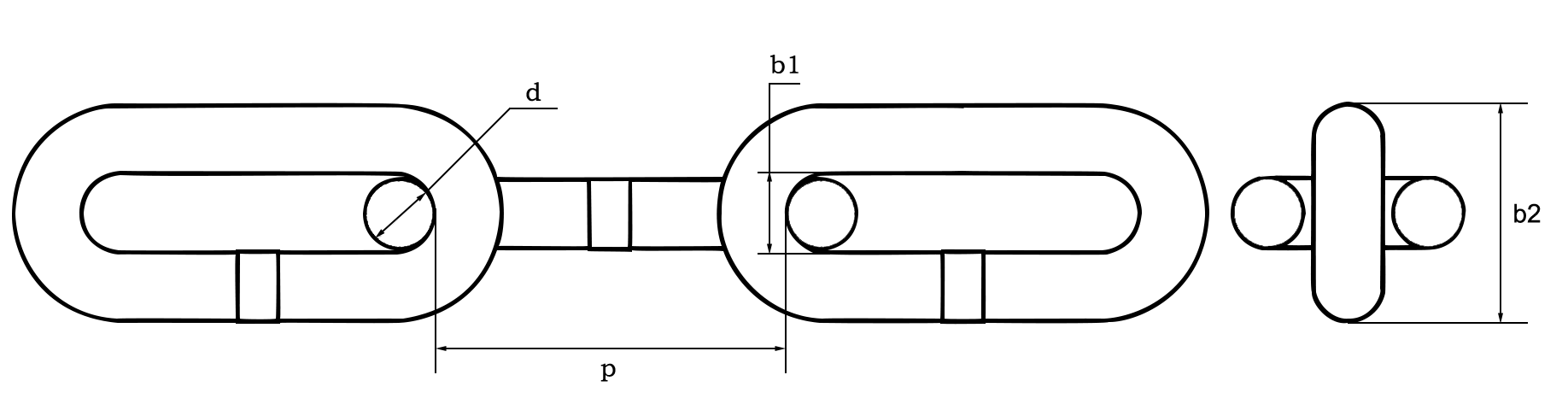

|

Diameter |

Pitch |

Inside Width min. |

Surface Treatment |

Working Load Limited |

Proof Load |

Breaking Load |

Weight |

|

d |

p |

b1 |

WLL |

MPL |

MBL |

||

|

mm |

mm |

mm |

kg |

KN |

KN |

Kg/m |

|

|

9 |

57 |

16 |

Painted |

2.5 |

50 |

100 |

1.5 |

|

11 |

72 |

18 |

Painted |

3.75 |

75 |

150 |

2.0 |

|

13 |

82 |

24 |

Painted |

5 |

100 |

200 |

2.9 |

!This product is not recommended for overhead lifting. It is strictly prohibited to use it in excess of the working load (WLL).

!Any surface coating will affect the mechanical properties of the chain.Please ask staff for details.

!Do not weld other accessories directly to the chain when used on deck.

We follow standards:

EN 818-1

EN 818-2

Optional surface treatment: natural black, powder coating, black electrophoresis, electro-galvanizing, hot-dip galvanizing, Dacromet.

Ambient temperature during use:

Min.: -40 ℃

Max.: 200 ℃

If the application scenario exceeds or is lower than the recommended operating temperature, please consult the staff to see if it is feasible.