Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

In demanding lifting environments, the choice of chain material and rigging components can define both safety and service life. A stainless lifting chain provides excellent corrosion resistance for marine, chemical, and food-grade industries, while steel and tube chain and rigging offer robust solutions for construction, logistics, and mining operations.

This article highlights the features, applications, and safety aspects of stainless steel chains and steel & tube rigging components. All solutions are manufactured and supplied under the TOPONE CHAIN® brand, ensuring international certifications and consistent quality.

A stainless lifting chain is made from high-grade stainless steel (such as AISI 304 or 316). Unlike standard alloy steel chains, stainless chains are designed for environments where rust and chemical exposure are primary concerns.

Key features of stainless lifting chains:

Corrosion resistance in saltwater, acidic, or chemical conditions.

Hygienic properties suitable for food processing and pharmaceutical industries.

Temperature stability for both high and low operating ranges.

Low maintenance with longer service life compared to untreated steel.

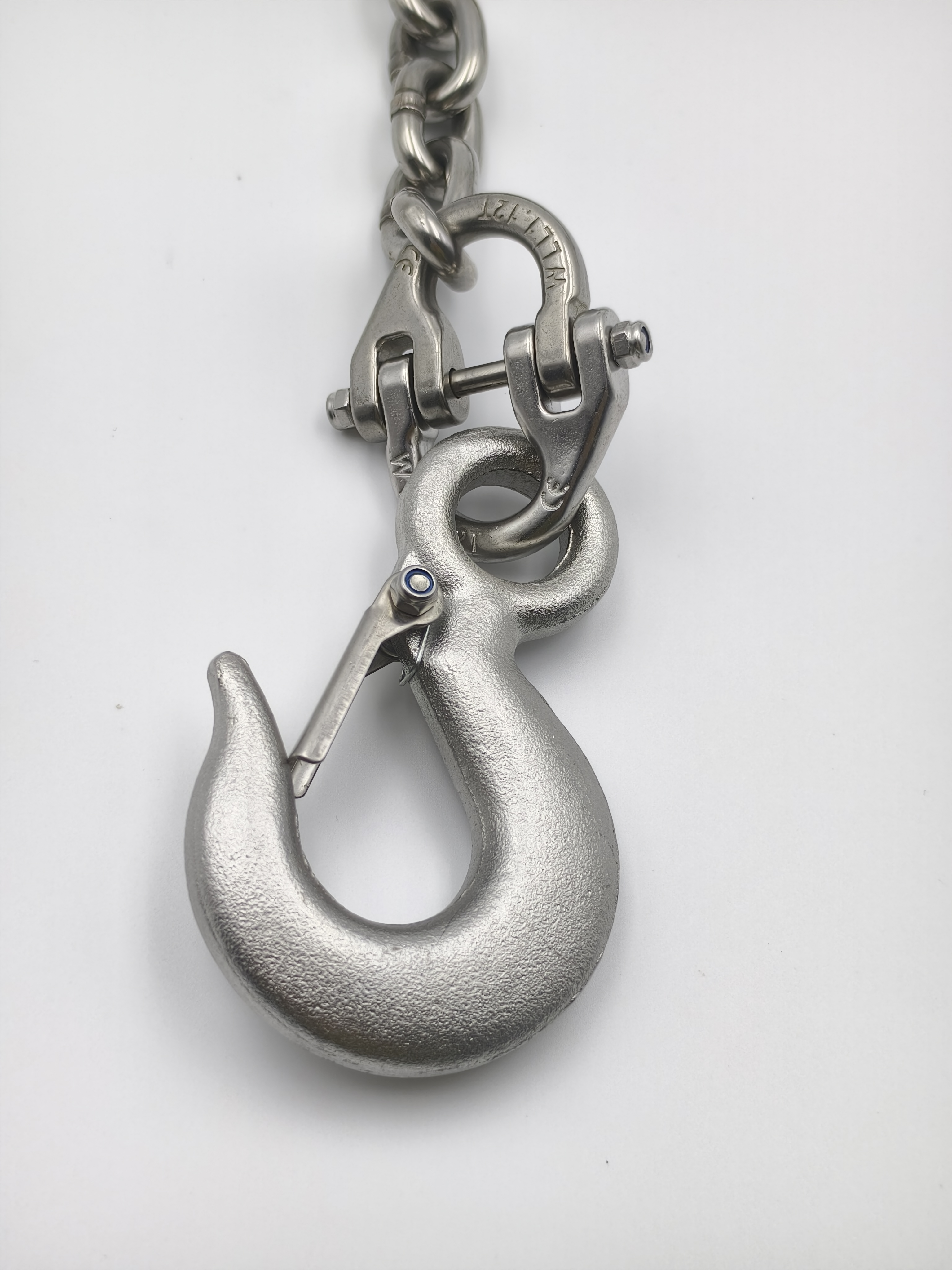

The term steel and tube chain and rigging refers to heavy-duty chain assemblies combined with fittings such as hooks, shackles, and master links, often supplied by steel and tube distributors. These assemblies are widely used for construction, transport, and general industrial lifting.

Typical components include:

Alloy steel chains (G80 or G100).

Hooks (grab hooks, self-locking hooks, foundry hooks).

Master links and coupling links.

Shackles and rigging hardware.

Marine & Offshore: anchor handling, mooring, shipyard operations.

Food & Beverage: hygienic lifting in processing facilities.

Chemical plants: resistant to acidic and corrosive environments.

Construction: lifting steel beams, precast concrete, and scaffolding.

Mining & Heavy Industry: moving equipment and bulk material.

Transport & Logistics: securing oversized cargo.

Feature | Stainless Lifting Chain | Alloy Steel Lifting Chain (G80/G100) |

Material | Stainless steel (AISI 304/316) | Quenched & tempered alloy steel |

Corrosion Resistance | Excellent (saltwater & chemicals) | Moderate (can be coated/galvanized) |

Strength | Lower than alloy steel | Higher load capacity per diameter |

Applications | Marine, chemical, food-grade | Construction, mining, heavy lifting |

Cost | Higher (premium material) | More economical for heavy-duty use |

Both stainless lifting chain and steel and tube chain and rigging must be used with proper safety practices:

Confirm Working Load Limit (WLL) before every lift.

Ensure accessories (hooks, shackles, links) match the chain grade.

Inspect chains for deformation, cracks, or corrosion.

Avoid mixing incompatible metals to reduce galvanic corrosion.

Store chains properly—stainless in dry, clean areas; alloy chains away from chemicals.

TOPONE CHAIN® provides both stainless steel lifting chains and alloy steel rigging systems with:

CE, TÜV, ISO9001 certifications for international markets.

Wide product range: stainless chains, G80/G100 alloy chains, and full rigging accessories.

Nine automated production lines with annual output of 500,000+ chains.

Customizable solutions: tailored diameters, coatings, and fittings.

Global delivery with strong supply chain support.

A stainless lifting chain is the best choice for corrosion-prone or hygienic environments, while steel and tube chain and rigging assemblies provide the strength and versatility required in construction and industrial lifting.