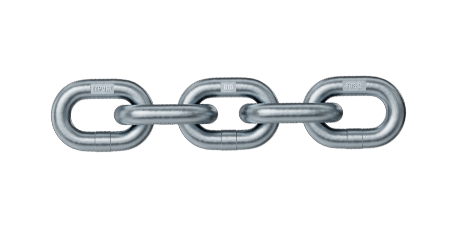

Surface Treatment

Any surface treatment other than self color (surface polish) will reduce the mechanical properties of the chain. The surface treatment used for round link chains depends on the purpose. Some application scenarios require wear resistance, some application scenarios require corrosion resistance, some application scenarios require both wear resistance and anti-corrosion, and some application scenarios only require color as a representation. We can provide surface polishing, carburizing/carbonitriding, electro-galvanizing, hot-dip galvanizing, powder coating, baking paint, electrophoresis,black oxide, aluminum plating, titanium plating, etc. If you're not sure what kind of surface treatment you need, please contact our technicians, all advice is free!