Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

TOPONE® high wear-resistant round link chains are available in a variety of hardness. They are particularly suitable for scraper conveyors and high-hardness geology or materials. The surface hardness can reach up to 64HRC. Carburizing treatment is available.

There are three types of wear-resistant chains produced by TOPONE®

1.TOPONE® tempering (LTT) G90

sacrifice elongation to increase breaking load and hardness (40~42HRC or 390HB), Elongation 14%

2.TOPONE® Quenching (QO) G60

sacrifice elongation and breaking load to increase overall hardness (45~47HRC or 450HB), Elongation 10%

3. Carbonitriding (C-N) G40

Through carbonitriding, a hard shell is formed on the surface of the chain (depth: up to 15% of the chain diameter, hardness: up to 64HRC or 800HV), and the core is soft with a certain elongation (relative elongation 1~3.5%).

|

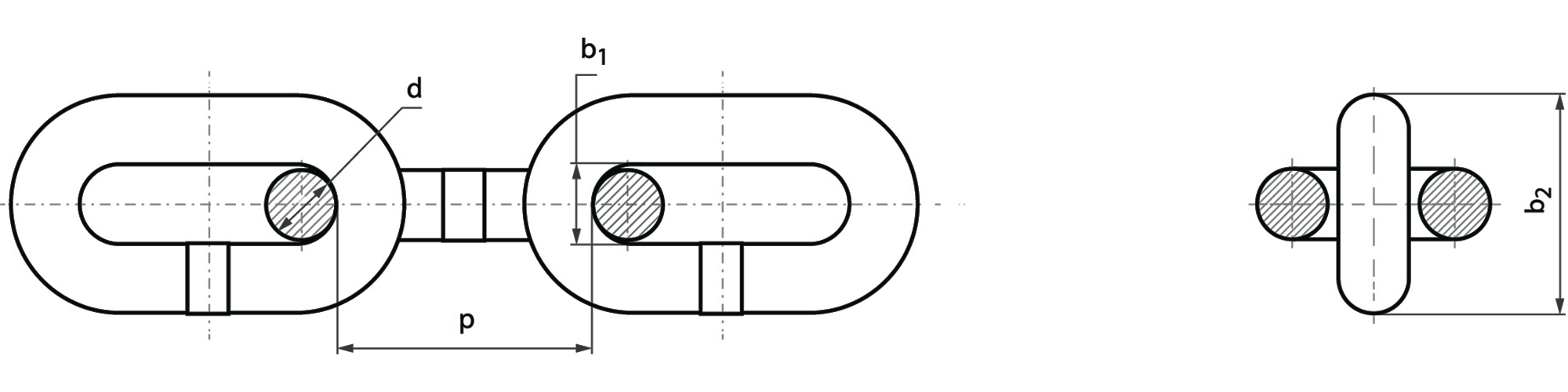

Dimension |

|||||

|

Chain Size d x p |

Diameter d |

Pitch P |

b1 min. |

b2 max. |

Weight |

|

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(kg/m) |

|

14 x 50 |

14 ±0.4 |

50 ±0.5 |

17 |

48 |

4.0 |

|

18 x 64 |

18 ±0.5 |

64 ±0.6 |

21 |

60 |

6.6 |

|

19 x 64.5 |

19 ±0.6 |

64.5 ±0.6 |

22 |

63 |

7.4 |

|

22 x 86 |

22 ±0.7 |

86 ±0.9 |

26 |

73 |

9.5 |

|

24 x 86 |

24 ±0.7 |

86 ±0.9 |

28 |

79 |

11.6 |

|

24 x 87.5 |

24 ±0.7 |

87.5 ±0.9 |

28 |

79 |

11.5 |

|

26 x 92 |

26 ±0.8 |

92 ±0.9 |

30 |

85 |

13.7 |

|

30 x 108 |

30 ±0.9 |

108 ±1.1 |

34 |

97 |

18.0 |

|

34 x 126 |

34 ±1.0 |

126 ±1.3 |

38 |

110 |

22.7 |

|

38 x 126 |

38 ±1.1 |

126 ±1.4 |

42 |

121 |

30.1 |

|

38 x 137 |

38 ±1.1 |

137 ±1.4 |

42 |

121 |

29.0 |

|

42 x 137 |

42 ±1.1 |

137 ±1.4 |

48 |

137 |

36.9 |

|

42 x 146 |

42 ±1.1 |

146 ±1.5 |

48 |

137 |

36.0 |

|

Mechanical Properties |

||||

|

Chain Size d x p (mm) |

Characteristic |

Chain Grade |

Test Force (KN) |

Breaking Force min. (KN) |

|

14 x 50 |

LTT |

G90 |

218 |

277 |

|

QO |

G60 |

146 |

185 |

|

|

C-N |

G40 |

97 |

123 |

|

|

18 x 64 |

LTT |

G90 |

361 |

458 |

|

QO |

G60 |

240 |

305 |

|

|

C-N |

G40 |

163 |

203 |

|

|

19 x 64.5 |

LTT |

G90 |

403 |

510 |

|

QO |

G60 |

268 |

340 |

|

|

C-N |

G40 |

179 |

227 |

|

|

22 x 86 |

LTT |

G90 |

540 |

684 |

|

QO |

G60 |

360 |

456 |

|

|

C-N |

G40 |

240 |

304 |

|

|

24 x 86 24 x 87.5 |

LTT |

G90 |

643 |

814 |

|

QO |

G60 |

426 |

540 |

|

|

C-N |

G40 |

285 |

362 |

|

|

26 x 92 |

LTT |

G90 |

754 |

955 |

|

QO |

G60 |

503 |

637 |

|

|

C-N |

G40 |

335 |

425 |

|

|

30 x 108 |

LTT |

G90 |

1003 |

1270 |

|

QO |

G60 |

669 |

848 |

|

|

C-N |

G40 |

446 |

565 |

|

|

34 x 126 |

LTT |

G90 |

1291 |

1635 |

|

QO |

G60 |

860 |

1089 |

|

|

C-N |

G40 |

573 |

726 |

|

|

38 x 126 38 x 137 |

LTT |

G90 |

1611 |

2040 |

|

QO |

G60 |

1074 |

1360 |

|

|

C-N |

G40 |

715 |

906 |

|

|

42 x 137 42 x 146 |

LTT |

G90 |

1968 |

2492 |

|

QO |

G60 |

1312 |

1662 |

|

|

C-N |

G40 |

875 |

1108 |

|

!This product is strictly prohibited from being used for overhead lifting.

!Any surface coating will affect the mechanical properties of the chain.Please ask staff for details.

!Enhanced performance chains are not recommended for use in harsh, corrosive environments, as pitting and friction martensite may lead to operational failures.

!Case-hardened chains can be loaded only with a force that is longitudinal to chain axis.

We follow standards:

DIN 17115

Acc. to DIN 22252 or PN-G-46701 or GB/T-12718 or GOST 25996

DIN 50100

DIN EN ISO 148

DIN EN ISO 6506

Optional surface treatment: natural black, powder coating, black electrophoresis, electro-galvanizing, hot-dip galvanizing, Dacromet.

Ambient temperature during use:

Min.: -40 ℃

Max.: 200 ℃

If the application scenario exceeds or is lower than the recommended operating temperature, please consult the staff to see if it is feasible.